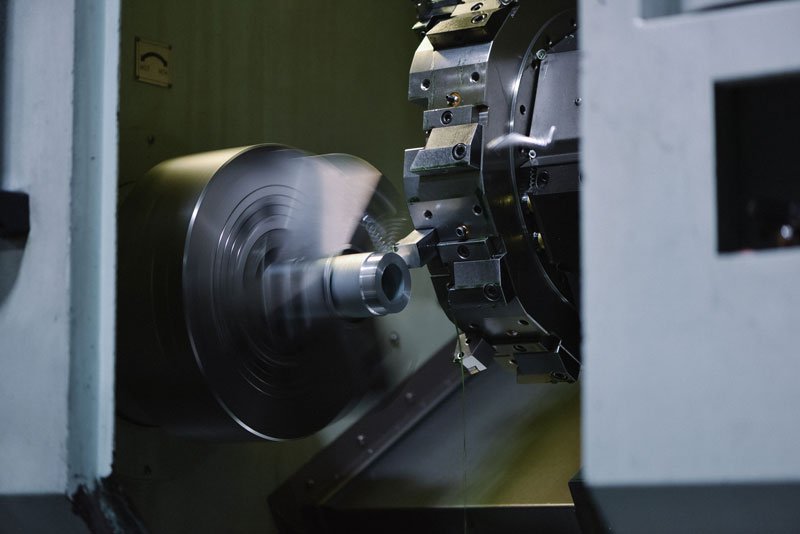

Machining

Utilizing the latest technology, our portfolio of CNC equipment is optimized and engineered to support your high–capacity, short lead–time requirements. Our diverse equipment list includes more than 50 pieces of CNC equipment complimented by an array of grinding, broaching, sawing, and multi–spindle turning capability.

Fabrication

Qualified under an array of ASME and AWS procedures, our fabrication and welding capabilities are designed to support your critical fabrication requirements.

Secondary Services

Experience and expertise allow us to provide turn–key solutions to improve your value stream. We offer an array specialty plating, finishing, heat treating, third party testing options.

Assembly

We utilize advanced ERP processes and detailed work instructions to facilitate light assembly, kitting, and custom packaging solutions to help customers reduce handling and improve shelf life.

Testing

From visual inspections to advanced NDE, our Quality team is capable of supporting an array of testing and inspection techniques critical to the quality and integrity of your product.

Inventory Management

Utilizing Supply Chain best practices and enhanced scheduling systems, we are able to offer inventory options tailored to support exceptional service and lead time. We are experienced in structuring JIT, Kan–Ban, and consignment programs to solve your inventory and warehousing constraints.